Детали за производот

Сертификација: CE / FDA

Услови за плаќање и испорака:

Минимална количина на нарачка: 1 СЕТ

Цена: Договор со УСД

Детали за пакување: Дрвена кутија со појас за врзување на железо

Време на испорака: 15 - 30 работни дена

Услови за плаќање: T / T, L / C, Western Union

Способност за снабдување: 2000 единици годишно

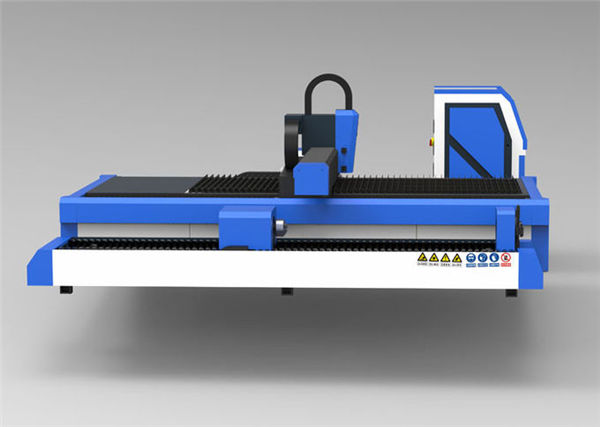

Детален опис на производот

| Подрачје за сечење: | 1500 * 3000мм | Режим на ладење: | Ладење на вода |

|---|---|---|---|

| Ласерска моќност: | 1500W | Контролен софтвер: | Ципче |

| Состојба: | Ново | Максимална работна маса: | 1000 кг |

| ЦПУ или не: | Да | Ласерска бранова должина: | 1060-1080nm |

| Точност за позиционирање: | ± 0,05 мм | Работен напон: | 380V / 50Hz |

Опис на производот

1. The machine is welded with a high-intensity whole sheet, and after high temperature annealing,the machine can be used for 20 years without any deformation.

2. With imported precision gear and rack, linear guide rail and transmission,the machine tool is of high precision, high efficiency and high stability.

3. Equipped with advanced wireless handheld terminal,the machine can be operated with remote control.

4. The equipment adopts the laser special speed matching system, high performance servo motor drive, is the integration of pneumatic, mechanical, photoelectric, numerical control and other advanced technologies as one of the high-tech products.

Карактеристики

1. Excellent overall performance, changeable working tables, 7 seconds to finish high speed changing, improve working efficiency of more than 48%.

2. The machine tool includes loading area and processing area, standard configuration is changeable working tables, auto change the workpiece between processing area and loading area by motor, convenient to upload and download. With the design of changeable working table, could prepare the next uploading while processing, highly improved working efficieny.

3. Equipped with exhaust device, have good exhausting effect and little pollution.

4. Small occupied area, high system integration, convenient to operate and maintenance, 24 hours continuous working.

5. The water chiller has good safety protection function, such as over temperature, lack phase, pressure, water-break, undervoltage, overload, etc. With stable performance, satisfied the cooling requirement of laser source.

Fiber Laser Cutting Machine Different Laser Sources Comparing

| Model of Laser Source | Влакна | CO2 | Disc |

| Electro-optical Conversion Efficiency | 30% | 10% | 15% |

| Max. Output | 50Kw | 20Kw | 8Kw |

| BPP(4/5Kw) | <2.5 | 6 | 8 |

| Life of Diode Pumped | >100,000 | NA. | 10,000 |

| Occupied Area(4/5Kw) | <1M2 | 3M2 | >4M2 |

| Maintenance | no need | need | Often |

| Soft Processing | more suitable | unsuitable | suitable |

| Stability | best | good | good |

| Absorption rate%--steel | 35 | 12 | 35 |

| Absorption rate%--aluminum | 7 | 2 | 7 |

| Replaced Parts | High brightness semiconductor laser broadband single core, more than 100,000 hours of pump. Damage to one of the semiconductor does not affect the normal work of the laser, but less and less power, because each semiconductor pump sources are used to separate each other. | Laser work requires gas supplement, reflection lens replacement. | Semiconductor Bar (array) maximum pulse model 5000 hours or 10000 hours continuous mode. Laser use the pump sources are used in the process of often need to change, each time change need to be between $200,000-230,000. |

Applied materials of 1500W Fiber Laser Cutting Machine

Фибер секач главно се користи за сечење на јаглероден челик, благ челик, нерѓосувачки челик, силициум челик, легура на алуминиум, легура на титаниум, галванизиран челичен лим, мариноване табла, алуминиумска цинк плоча, бакар и многу видови метални материјали. Тоа е CNC ласерски секачи може да се користи за да се направи прецизно сечење. Исто така, може да се нарече машина за сечење влакна, ласерски машина за оптички влакна, ласерски машина за метал, секач за влакна, сечење на јаглероден челик, CNC ласерски секачи.

Технички параметар

| Работна површина | 3000 * 1500мм |

| Контролер + следбеник на височина | Ципче |

| Извор на ласер | Fiber Laser Source 1500W |

| Должина на бранови | 1070nm ± 10nm |

| Ласерска глава | Изборен |

| Опрема и решетката | Германија |

| Водич Railелезнички | Тајвански HIWIN |

| Прецизирање на позиционирање | ≤ 0,04 мм |

| Сечење на дебелина | 1-20мм |

| Максимална брзина на сечење | 40000мм / мин (според материјали) |

| Работен напон | AC220V / 110V ± 10% 50HZ / 60HZ |

| Ширина на мин линијата | .120,12 мм |

| Трансмисија | Редуктор на Yaskawa servo 850W + FASTON |

| З-оска | Кочница Јаскава 400W + |

| Ладење | Ладење на вода |

| Структура | 10 mm дебелина заварена челична цевка, алуминиумска легура на алуминиум |

| Потрошувачка на енергија | .5 7,5KW |

Performance for 1500W Fiber Laser Cutting Machine

1.The machine enjoys outstanding performances with high cutting speed, high efficiency, safety and stability. And diode pump solid state laser has the advantage of longer working life, free maintenance and the highest photo-electric conversion efficiency. It also ensures a small divergence angle and light beams of good quality.

2. The light spot enjoys good quality and small heat deformation. Besides, cutting seams are even and nice.

3. After tempering treatment, steel frames with high rigidity are of high vibration-absorbed performance with tempering treatment. And frames with gantry structure are one-step processed in large CNC gantry machining center. With optimized structure, the machine enjoys stability and high accuracy.

4. Imported servo motors and sophisticated direction transmission mechanism ensure high steadiness and accuracy.

5. An intuitive human-machine interface (HMI) with many practical functions is easy to operate.

6. An imported ball screw and linear guides ensure transmission and direction.

7. The sealed cutting head automatically tracks work pieces and has the function of anti-collision.

8. The power supply of the machine is designed with automatic safety protection, and features fault alarm.

9. With fashionable, delicate and artistic design, the compact machine covers smaller floor area without scattered parts. And it’s easy to operate the machine.